One of the biggest challenges when selecting appropriate cables for a specific application is finding the optimal balance between flexibility, strength or durability, and safety and cost effective – especially where extreme environmental conditions are involved.

In this blog post, we will be discussing the various factors to consider when selecting cables, with a focus on armoring and jacketing materials for optimized cable flexibility and strength. To ensure the most suitable cable is selected for a specific application, and that optimized flexibility does not come at the expense of strength or safety, various factors need to be accurately identified, evaluated and prioritized.

Applications that require cable flexibility

Most cable systems need to tolerate some level of movement. This can be small amounts of movement during initial installation, or larger amounts of movement in the case of temporary and repeated installations or multi-deployment such as cables used for outdoor events or tactical cables used in the Defense industry. These cables require a higher level of built-in flexibility (also referred to as flex or suppleness) so that they can withstand pulling, flexing and bending when they are repeatedly coiled up, packed away, and redeployed.

What is flexibility?

In simple terms, flexibility is the measure of how much movement a cable can endure in a given time. A cable’s flexibility is tested when it is twisted, bent, or pulled into positions that are different from its original state. Flexible cables can be bent significantly for long periods of time whilst still maintaining their mechanical and communication properties without permanent damage.

What is flex life?

Though sometimes confused with cable flexibility, flex life actually deals less with how a cable moves and more with how often it can move without damage or degradation. While most cables can bend to some degree for a limited number of times (for example, during installation), a high flex cable can be bent repeatedly and without adversely affecting its intended use.

As is the case with flexibility and other cable features such as mechanical strength, crush resistance and fire-resistance, these parameters should be determined based on the intended application and the environmental conditions where the cable will be located. So if the cable needs to be easily moved, it should be flexible and if it needs to move often, it should have a high flex life. In some applications, for example for the Defense industry, cables need to be both flexible and have a high flex life.

<<Contact us to find out how you can optimize your cable for flexibility, strength and safety>>

What makes a cable flexible?

Now that we’ve established why some cables need to be more flexible than others, let’s look at what actually makes a cable flexible. There are four main factors that impact cable flexibility.

- Cable conductors

Two types of wires are commonly used to transmit power or signals through a cable – solid wire and stranded wire. The conduction path in a solid cable is a single wire, which is usually made from copper. Solid cables are normally more cost-efficient than stranded cables and offer excellent performance with relatively low resistance. However, solid cables are not as flexible so they are less suitable for applications requiring cable flexibility.

In stranded cables, the conductors are comprised of multiple strands that are twisted together to form a thicker wire. As a rule of thumb, when choosing stranding for cables that undergo frequent and repeated flexing and bending, a higher strand count is best as the more strands there are in a cable, the more flexible the cable. There are two types of stranded cable configurations – a rope lay construction and a concentric construction.

In concentric strands, a solid conductor runs down the center and is surrounded by layers of rotating strands. In terms of movement and motion endurance, the rope lay construction is the most flexible configuration. In this configuration, multiple bundles of stranding are twisted into groups to make up a larger, solid configuration. That said, it is also one of the more expensive options and is an excellent example of the trade-offs that engineers and buyers need to make when selecting cable materials for specific applications.

- Strength members

Strength members are used to preserve cable integrity and enhance resistance to different types of movement such as torsion, pulling, bending and rolling. They can be made from various compounds such as aramid fiber, steel or a stiff fiberglass rod that runs the length of the center of the cable – all of which affect the flexibility levels of the cable.

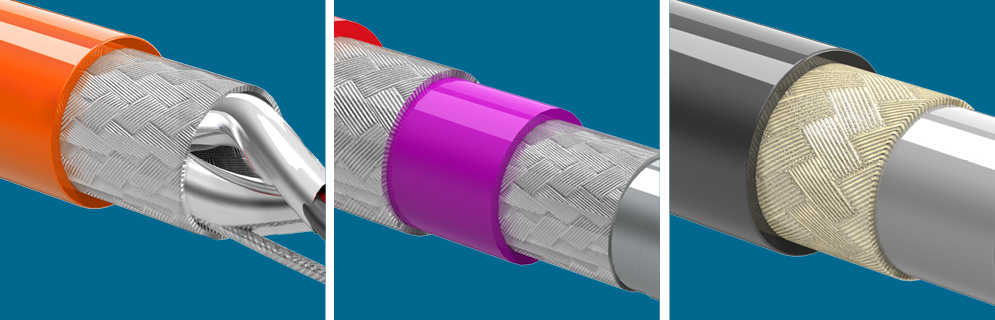

- Jacket and armoring materials

Cable armoring is used to protect underlying conductors from mechanical, moisture and chemical damage. It can also serve as an Earth Continuity Conductor (ECC), protect against harsh environmental conditions such as crushing forces, rodents and UV radiation, and provide enhanced flame resistance.

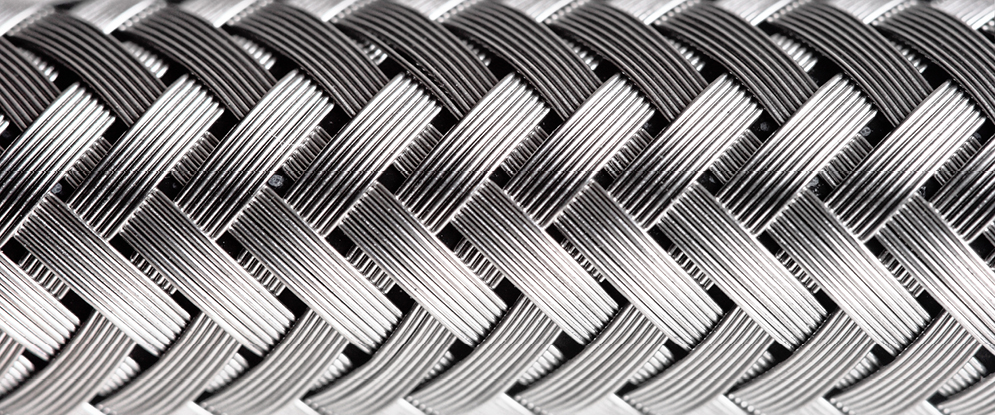

Cable armor comes in different constructions, including woven braids, tape or interlocking covers. Braided armor offers more flexibility than tape armor as the interwoven wires allow for bending and stretching with less chance of buckling, folding or kinking.

Some cable armoring materials offer more flexibility than others. Here are some examples:

|

Category |

Material |

Level of Flexibility |

|

Metal-braid armor |

Galvanized (zinc-plated) steel |

Flexible |

|

Stainless steel |

Flexible |

|

|

Bronze |

Flexible |

|

|

Copper |

Flexible |

|

|

Steel wire armor (SWA) |

Galvanized steel |

Less flexible than braided galvanized steel armor as the wires are thicker. However, it still offers more flexibility than corrugated tape armoring options. |

|

Steel tape armor (STA) |

Corrugated steel |

Rigid |

|

Copper tape armor |

Copper |

Rigid |

|

Dielectric armor |

Polymer |

Highly flexible |

|

Non-dielectric armor |

Glass-yarns |

Highly flexible |

In addition, cable jacketing materials can be used to further protect the cable from harsh elements such as chemicals, oil and sunlight and to prevent cable failure as the result of impact and abrasion. Here too, some materials offer more flexibility and/or strength than others. Teldor offers a variety of proven insulating and jacketing materials that offer different levels of flexibility, strength and fire-resistance for Defense, Shipboard and Harsh Environment applications. For more information about these materials, click here.

<<Contact us to find out how you can optimize your cable for flexibility, strength and safety>>

- Shielding

Shielding is used to enhance the cable’s structural and signal integrity, and to protect it against external environmental conditions such as water ingress, chemical exposure, and UV exposure. It is applied over armoring in the case of armored cables and over the inner sheath in the case of unarmored cables. Different shielding materials and configurations will affect parameters such as coverage, strength, flexibility and EMI reduction.

The main types of shields are foil shields, box weave or basket weave braid shields, and spiral shields:

- Foil shields offer 100% coverage without adding much weight or cost. However, they may crack or unfold when flexed, so they are less suited to applications requiring high flex life.

- Box weave or basket weave braid shields offer a more flexible solution. However, as they are made up of small strands of conductors woven into a sleeve around the cable, they have small gaps and cannot reach 100% coverage. Multiple layers of braid can be used to overcome this challenge and achieve a higher level of coverage.

- Spiral shields offer a high level of flexibility, but may have a shorter life span in high flex environments and applications.

Some cables are available with combined foil and braided shielding. This increases coverage but also reduces the cable’s level of flexibility.

Teldor can help you find the right combination of flexibility, strength and fire-resistance for your specific application

We hope that this blog post has given you valuable insights about how various factors and materials affect the flexibility, strength and flammability rating of cables. As each of these requirements and combination of requirements differ per application, it’s important to understand the needs of your specific application to ensure that the right cable construction is chosen.

Our engineers at Teldor have extensive experience in designing cable systems that offer the optimal combination of features for diverse industries, applications and environments. In addition to our vast range of standard cable solutions, we can also help you design specific cable systems for optimal performance and reliability in your specific application.

Contact us to find out how you can optimize your cable for flexibility, strength and safety.