A well-engineered cable is comprised of many different elements, each of which is critical to ensuring the cable performs its specific function in its specific environment and for its designed life span.

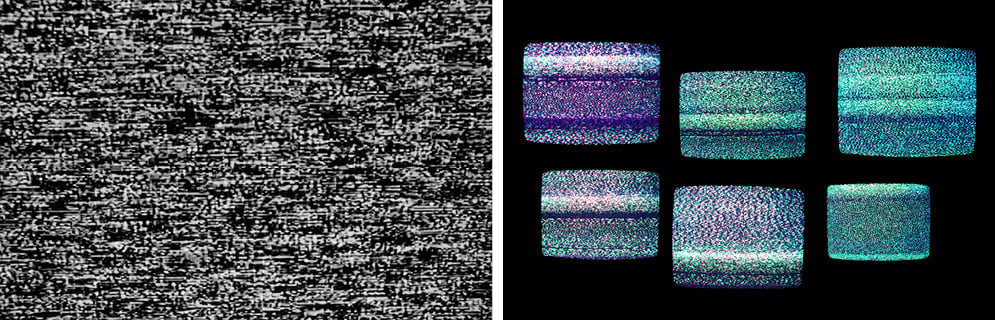

With the growing complexity of communication and control systems, together with the increase in the distance that signal and control communications need to travel, electrical interference (noise) and signal interference have also increased. This noise – which can be caused by electromagnetic, radio and electrostatic interferences (EMI, RFI, and ESI) – can adversely affect system performance.

How is EMI Generated?

EMI is basically electromagnetic waves that travel in the environment and are generated from multiple sources such as antennas, mobile phones, WiFi networks, a main electric grid satellite, motors and more. It can significantly impact communication networks, digital networks and computers in the vicinity of these sources.

Cables can act as a main source and receiver of EMI. As a source, cables can either conduct electronic noise to other equipment or radiate the noise like an antenna. As a receiver, they can pick up EMI from other sources as an antenna as well.

<<Contact us to learn more about our cable shielding options for EMI reduction>>

Electromagnetic Shielding for Cables

While jacketing protects a cable from mechanical abrasion, environmental moisture and spills, it doesn’t protect against signal interference and electronic noise such as EMI. Therefore, advanced shielding is needed to protect the cable from the effects of EMI from the environment and to prevent the cable from releasing EMI to the environment.

Electromagnetic shielding prevents, or at least reduces, the coupling of undesired radiated electromagnetic energy in systems and cables. Usually, the shielding comes in the form of a metallic barrier located in the path of the electromagnetic waves between their source and the device that needs to be protected.

Cable shielding is commonly used for data and signal cables, and its design and grounding is extremely important in the reduction of EMI effects. The factors that affect the type of shielding and final result differ per application and include cable lengths, signal frequency, noise frequency and cable termination methodology. It’s important to note that the improper shielding of the system can actually increase the EMI effect on a system’s performance.

<<Contact us to learn more about our cable shielding options for EMI reduction>>

When is EMI Shielding Required?

There are multiple cases that require cables with EMI shielding. The following are some examples:

- Regulatory restrictions and standards – when a product or system needs to meet specific standards

- Aerospace and military certified cables – when extra protection against EMI is required, for example against electromagnetic warfare and electromagnetic pulses (EMP)

- Safety and security systems – for the protection of sensitive instruments and mission-critical systems

- A need to increase cable performance and data transmission capacities for standard Ethernet communications

Types of Cable Shielding

As data or signal cables carry broadband signals (up to high frequency ranges), they require shielding to minimize radiated coupling and EMI. The shielding surrounds the signal carrying conductors of the cable and protects it by reflecting signal interference and picking up noise and conducting it to ground. It can be metallic, braided or sheets (either on each pair or in general on the cable itself).

There are two types of cable shielding:

- Foil Shields – Foil shielding uses a thin metallic layer, which is reinforced with a polymeric layer that can provide up to 100% shielding. However, this solution may reduce the flexibility of the cable.

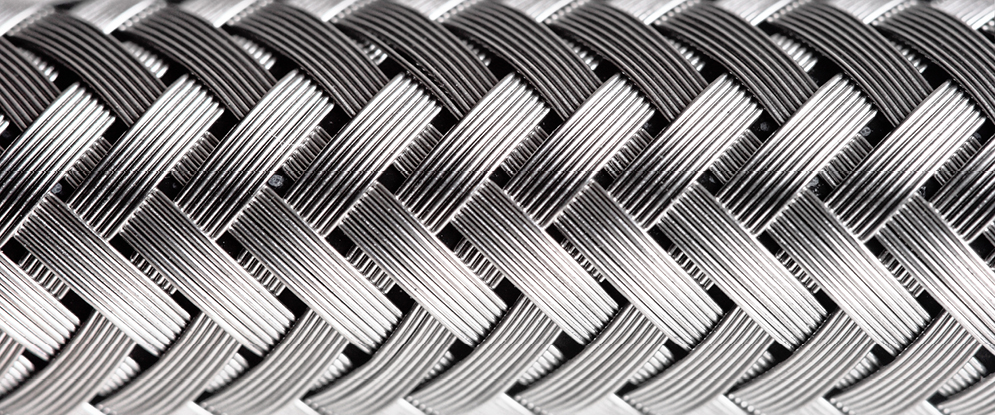

- Braided Shields – Braided shields are woven meshes of wires. They do not provide 100% coverage due to the gaps between the braids (they normally provide up to 95% coverage). That said, the braid conductivity (depending on the material of both shields) is superior, which is one of the key factors that contribute to shielding efficiency.

Many conductive materials have been developed and are now used for shielding cables for harsh environments and mission-critical industries. These materials offer a lighter weight, more tensile strength, enhanced durability and better shielding performance.

Different levels of EMI reduction and protection can be achieved through different combinations of materials, armoring and shielding, material density and more. For example, for environments requiring a high level of EMI protection such as Defense applications, multiple shielding layers can be combined for optimum protection.

Trusted Supplier of Shielded Cables for EMI Reduction

As a trusted supplier of cable solutions for a wide range of applications that require electromagnetic compatibility (EMC), Teldor combines its extensive knowledge, innovation, expertise, and material engineering know-how to advise our customers about the appropriate cable shielding options for their specific requirements and for optimal performance.

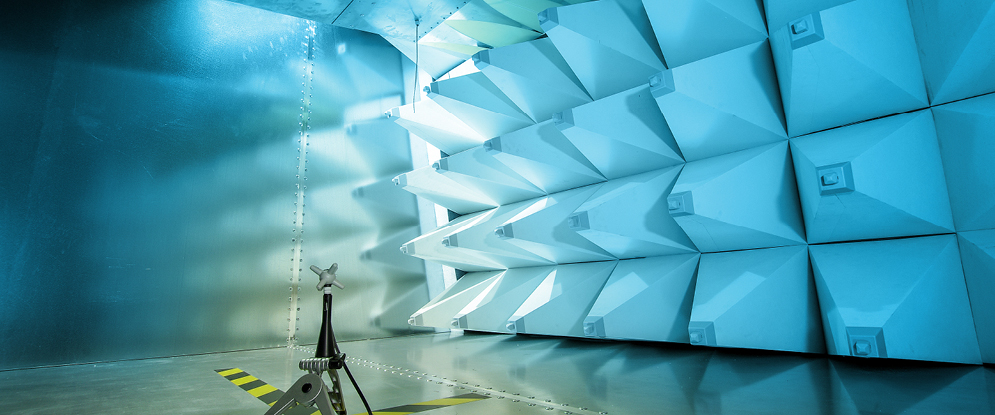

We use advanced measurement and testing procedures to verify that our cables meet specific EMI-related standards, and help our customers design cabling systems that offer optimal system performance, EMI reduction, and cost efficiency.